A hydraulic pump motor consists of three main parts: a reservoir, a pump, and a motor, which is used to harness mechanical energy. Read More…

It is our goal that we are able to maintain our position as one of the leading producers and manufacturers of hydraulic motors and that we may provide our products to an ever growing customer base worldwide! We were founded in 1941 and we wish to put all of those years of experience to work for you! To receive more information about how we may be able to benefit you; get in touch with our...

At Hyseco Inc., we specialize in providing high-quality hydraulic motors and related solutions designed to meet the diverse needs of industries that demand reliable, efficient power. Our extensive experience allows us to offer a range of hydraulic motors that deliver optimal performance, whether in demanding industrial applications or precision-driven processes.

Hader Industries is a manufacturer of hydraulic components. We custom-engineer hydraulic cylinders, valves and accumulators for mobile equipment. We have been servicing various industries for over 70 years. If you have any questions about our products or services then please give us a call today to learn more!

At International Fluid Power of America, we specialize in delivering innovative hydraulic solutions to meet the diverse needs of our clients. With a deep-rooted expertise in hydraulic systems, we focus on providing high-quality hydraulic motors that power industries across various sectors, including manufacturing, agriculture, construction, and more. Our hydraulic motors are engineered to deliver ...

More Hydraulic Pump Motor Manufacturers

Components

Hydraulic pump motors energize fluid to flow from a lower potential to a higher potential. It has several mechanical moving parts powered by different sources. The majority of hydraulic pumps contain revolving components powered by electricity. A hydraulic pump's outside casing shields the interior. Casings can be made of cast iron or aluminum.

Impeller blades revolve inside the casing, rotating the surround fluids. the blades also lubricate and cool the system. Pump bearings are often made to anti-friction, to help the impeller rotate inside the casing. The pump shaft is made of steel, and its size corresponds to the size of the impeller.

Working Principle of A Hydraulic Pump Motor

A hydraulic hand pump transforms human power into hydraulic energy by combining pressure and flow. The foundation for hydraulic fluid delivery is the simple notion that a handle gives an internal piston leverage under manual pressure. The piston then pushes the hydraulic fluid into the cylinder port. Water and hydraulic fluid are the two most common fluids, and however other pressure media can also be used.

The hydraulic pressure generated can be used to test, calibrate, and adjust various measuring instruments and tools. Hydraulic hand pumps are widely used to load and test mechanical parts when a user requires precise adjustments. They are also used in lifting and lowering heavy things in material handling equipment, which similarly necessitates precise control over the movement of the objects.

Different hydraulic pump types

-

Gear pumps

- External gear pumps

- Lobe pumps

- Internal gear pumps

- Reciprocating pumps

- Rotary pumps

- Gerotor pumps

- Screw pumps

- Piston pumps

- Axial piston pumps

- Radial piston pumps

- Vane pumps

The working medium, requisite pressure range, drive type, etc., are only a few of the functional and hydraulic system requirements that are considered when manufacturing hydraulic pumps. In addition, there are numerous design philosophies and hydraulic pump combinations to choose from. Due to this, only a few pumps can completely fulfill all needs. The most common types of hydraulic pumps have already been described.

Hydraulic pumps application

The use of hydraulic pumps is still common in industrial settings. Elevators, conveyors, mixers, forklifts, pallet jacks, injection molding machines, presses (shear, stamping, bending, etc.), foundries, steel mills, and slitters are examples of equipment used in material handling. With an application's need, a hydraulic pump is more likely to be used.

Additionally, hydraulic pumps are used in every conceivable mobile or industrial hydraulic machine. They are used on many different pieces of gear, such as excavators, cranes, loaders, tractors, vacuum trucks, forestry equipment, graders, dump trucks, and mining equipment. Mobile applications use hydraulic pumps more commonly than industrial applications since industrial devices typically don't use electric actuators.

Choosing the Proper Hydraulic Pump Motor Supplier

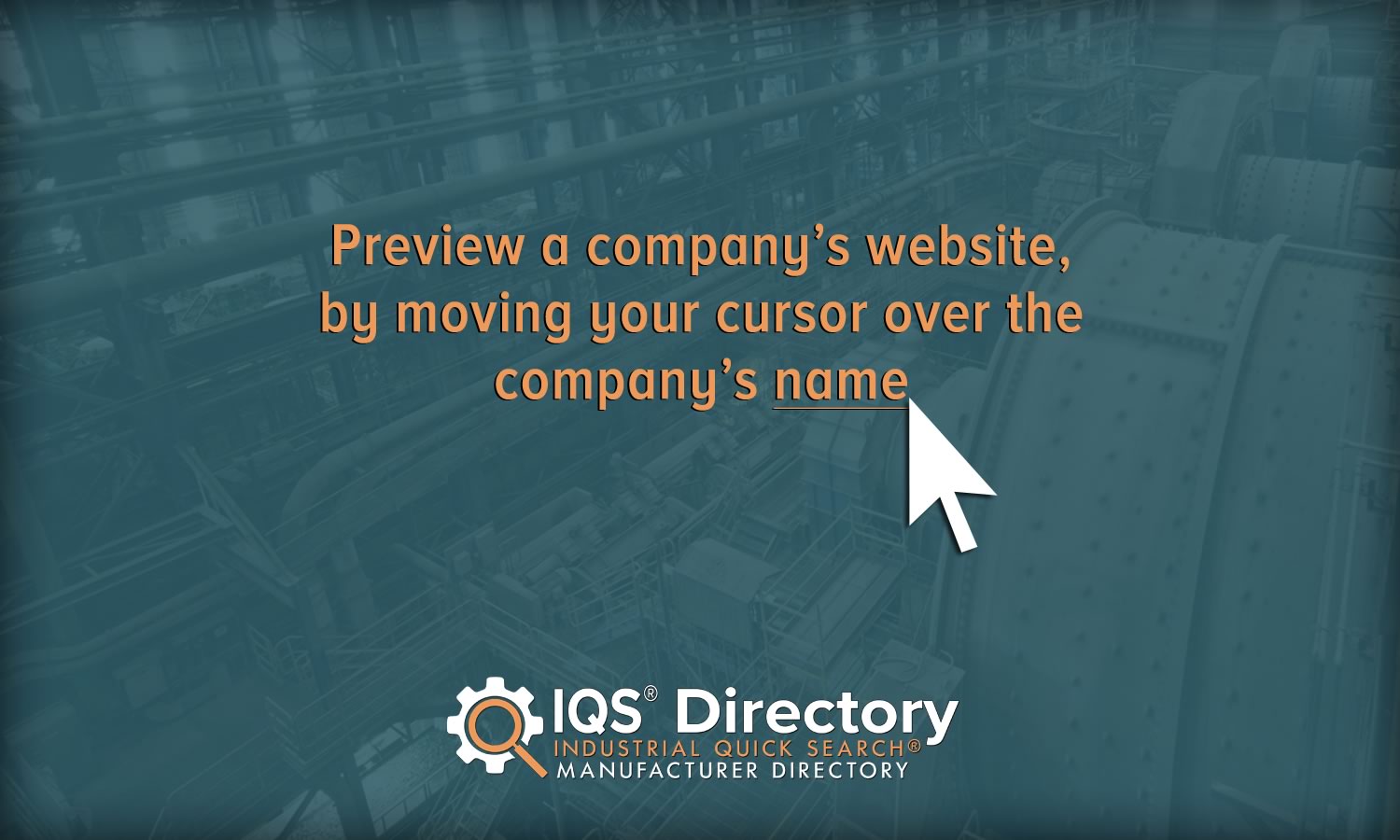

To ensure the most productive outcome when purchasing a hydraulic pump motor from a hydraulic pump motor supplier, it is important to compare several companies using our directory of hydraulic pump motor suppliers. Each hydraulic pump motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each hydraulic pump motor business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hydraulic pump motor companies with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services